Achievements

For future projects, I believe that an achievement for using little to no pneumatic devices would be extremely unique and challenging, as most groups used multiple in their projects. I also think that an achievement where you leave out a key component of the intended design (in our case we left out the magnets) which would encourage innovative and creative designs.

Helping Hand

Tom helped our group out early on by giving us a design tip. He was the one that showed us how to create pressure in our pneumatic system and how to wire the pneumatic motors a certain way that made it easier to program with.

Reflection

In my opinion, we accomplished our objectives very well. We were able to create an innovative and unique design that completed the process with a lot of time to spare. In the future, I think we would use a magnet instead of using our spring because the major flaw in our design was that we could only complete the process if the wooden marbles did not follow a metal marble. The results fulfill the problem statement very well because we were able to sort out all 5 different types of marbles into different bins in less than two minutes (1:20 seconds was roughly our time). Freddy and I have learned the importance of an attention to detail, because the smallest adjustments produce a misreading that leads to a failed attempt, whether it be with the bins that catch the marbles pushed off by the spring, or the gate that lets the photo resistor differentiate between the colors of the marbles. We have learned how to program as well, our program was very complicated and we used a couple subprograms to achieve our desired result. We had a few challenges that faced us with regard to working in a team, one of us would bump something that we had been working on fixing or change part of the program which instead of helping us take a step forward, made us take two steps back. The purpose of this design problem was to teach us to work in teams, be able to program and use the various Fisher robotics parts, and finally show us some of the skills needed to use later on in our engineering careers. These skills include: teamwork, attention to detail, perseverance, dedication, creativity, and most of all, the importance of consulting with our peers on common problems.

Final Design

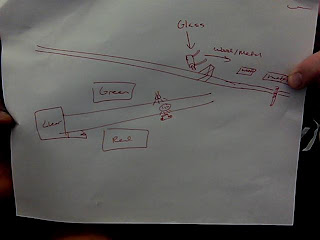

1. This is where our design begins This is the Compressor which builds the necessary pressure to operate the Pneumatics, and is stored in the blue container.

2 a. Here if the marbles are small enough, (either the wood or metal) the follow the track down the track where the heavier one (metal) will go past the spring and the lighter (wood ) will "spring backwards to a different bin

2. b. If the marble is too large to fit into wood and metal marble track it is stopped in front of the Pneumatic device which launches it onto another track.

4. On the next track the marble is stopped by our gate which is programed to hold the marble in place in front of the Photosensor to get an accurate reading of the marbles translucency.

5 Last, depending on what reading the photosensor gets it will fire one or none of the Pneumatics to either guide the marbles off the track or let it follow it all the way down the track.

6. Here is our main program. This program is responsible for seperating the metal/wooden marbles from the glass marbles (discussed in part 2)

7. Next, we have our glass program.

This was the part of the programming that took the most time to complete. We had to spend quite a few class periods to finally find the values that worked. When the marble arrives at the photoresistor, this program dictates what happens based on that reading. If the photo resistor gets a reading less than 240, it moves onto the next branch of the program. If its more than 240, the marble is placed in the bin on the right. The next branch takes that reading and if it is more than 200, then it is placed in the bin on the left. If it is less than 200, then nothing happens and it rolls into the bin waiting at the bottom of the ramp.

8. Lastly, we have our gate program. This program is responsible for controlling the gate that keeps the marble in the photoresistor long enough for it to get a reading.

We had to find times that worked so that the gate did not move to a different spot at any point during the trial. We found that the gate moved faster going down than it did going up, so, as you can see in the program, we made it go 1.5 seconds up and 1.4 seconds down to combat this problem.

Altogether we didnt have too many modifications to our machine

- Here we added another flat piece attached to the metal pole to prevent anymarble from being lauched too far and off of the track.

-Here we added another support beam in order to further stabilize our gate to get more consistent readings from our photosensor.

- To further stabilize our gate, in order to get consistent readings for the photosensor we added the flat red pieces to reduce any twisting or torquing of the building blocks.

- Also we flipped around the motor itself to reduce the amount of give it would have from going up and down.

We decided upon using the spring to seperate between the wooden and metal marbles in order to save time and wiring. Once calibrated, the marbles were consistently seperated so long as they didn't come through at the same time. We then chose to use a photoresistor to seperate the different colors between the marbles.

Reliability Time Efficiency Innovative total Pneumatic 2 3 4 3 12 Tree Design (magnets) 1 2 3 4 10 Spring 3 1 1 1 6 Photosensors 2 4 2 2 10

Because the pneumatics scored the worst, we tried to use as little as possible. The spring was extremely innovative, and required no power, only that it needed to be calibrated. The photo sensors worked well, but only when the marbles were opaque in nature. We decided to scrap magnets altogether because the spring would take care of the

Achievements

For future projects, I believe that an achievement for using little to no pneumatic devices would be extremely unique and challenging, as most groups used multiple in their projects. I also think that an achievement where you leave out a key component of the intended design (in our case we left out the magnets) which would encourage innovative and creative designs.

Helping Hand

Tom helped our group out early on by giving us a design tip. He was the one that showed us how to create pressure in our pneumatic system and how to wire the pneumatic motors a certain way that made it easier to program with.

Reflection

In my opinion, we accomplished our objectives very well. We were able to create an innovative and unique design that completed the process with a lot of time to spare. In the future, I think we would use a magnet instead of using our spring because the major flaw in our design was that we could only complete the process if the wooden marbles did not follow a metal marble. The results fulfill the problem statement very well because we were able to sort out all 5 different types of marbles into different bins in less than two minutes (1:20 seconds was roughly our time). Freddy and I have learned the importance of an attention to detail, because the smallest adjustments produce a misreading that leads to a failed attempt, whether it be with the bins that catch the marbles pushed off by the spring, or the gate that lets the photo resistor differentiate between the colors of the marbles. We have learned how to program as well, our program was very complicated and we used a couple subprograms to achieve our desired result. We had a few challenges that faced us with regard to working in a team, one of us would bump something that we had been working on fixing or change part of the program which instead of helping us take a step forward, made us take two steps back. The purpose of this design problem was to teach us to work in teams, be able to program and use the various Fisher robotics parts, and finally show us some of the skills needed to use later on in our engineering careers. These skills include: teamwork, attention to detail, perseverance, dedication, creativity, and most of all, the importance of consulting with our peers on common problems.

Final Design

1. This is where our design begins This is the Compressor which builds the necessary pressure to operate the Pneumatics, and is stored in the blue container.

2 a. Here if the marbles are small enough, (either the wood or metal) the follow the track down the track where the heavier one (metal) will go past the spring and the lighter (wood ) will "spring backwards to a different bin

2. b. If the marble is too large to fit into wood and metal marble track it is stopped in front of the Pneumatic device which launches it onto another track.

4. On the next track the marble is stopped by our gate which is programed to hold the marble in place in front of the Photosensor to get an accurate reading of the marbles translucency.

5 Last, depending on what reading the photosensor gets it will fire one or none of the Pneumatics to either guide the marbles off the track or let it follow it all the way down the track.

6. Here is our main program. This program is responsible for seperating the metal/wooden marbles from the glass marbles (discussed in part 2)

7. Next, we have our glass program.

This was the part of the programming that took the most time to complete. We had to spend quite a few class periods to finally find the values that worked. When the marble arrives at the photoresistor, this program dictates what happens based on that reading. If the photo resistor gets a reading less than 240, it moves onto the next branch of the program. If its more than 240, the marble is placed in the bin on the right. The next branch takes that reading and if it is more than 200, then it is placed in the bin on the left. If it is less than 200, then nothing happens and it rolls into the bin waiting at the bottom of the ramp.

8. Lastly, we have our gate program. This program is responsible for controlling the gate that keeps the marble in the photoresistor long enough for it to get a reading.

We had to find times that worked so that the gate did not move to a different spot at any point during the trial. We found that the gate moved faster going down than it did going up, so, as you can see in the program, we made it go 1.5 seconds up and 1.4 seconds down to combat this problem.

2 a. Here if the marbles are small enough, (either the wood or metal) the follow the track down the track where the heavier one (metal) will go past the spring and the lighter (wood ) will "spring backwards to a different bin

2. b. If the marble is too large to fit into wood and metal marble track it is stopped in front of the Pneumatic device which launches it onto another track.

4. On the next track the marble is stopped by our gate which is programed to hold the marble in place in front of the Photosensor to get an accurate reading of the marbles translucency.

5 Last, depending on what reading the photosensor gets it will fire one or none of the Pneumatics to either guide the marbles off the track or let it follow it all the way down the track.

6. Here is our main program. This program is responsible for seperating the metal/wooden marbles from the glass marbles (discussed in part 2)

7. Next, we have our glass program.

This was the part of the programming that took the most time to complete. We had to spend quite a few class periods to finally find the values that worked. When the marble arrives at the photoresistor, this program dictates what happens based on that reading. If the photo resistor gets a reading less than 240, it moves onto the next branch of the program. If its more than 240, the marble is placed in the bin on the right. The next branch takes that reading and if it is more than 200, then it is placed in the bin on the left. If it is less than 200, then nothing happens and it rolls into the bin waiting at the bottom of the ramp.

8. Lastly, we have our gate program. This program is responsible for controlling the gate that keeps the marble in the photoresistor long enough for it to get a reading.

We had to find times that worked so that the gate did not move to a different spot at any point during the trial. We found that the gate moved faster going down than it did going up, so, as you can see in the program, we made it go 1.5 seconds up and 1.4 seconds down to combat this problem.

Altogether we didnt have too many modifications to our machine

- Here we added another flat piece attached to the metal pole to prevent anymarble from being lauched too far and off of the track.

-Here we added another support beam in order to further stabilize our gate to get more consistent readings from our photosensor.

- To further stabilize our gate, in order to get consistent readings for the photosensor we added the flat red pieces to reduce any twisting or torquing of the building blocks.

- Also we flipped around the motor itself to reduce the amount of give it would have from going up and down.

We decided upon using the spring to seperate between the wooden and metal marbles in order to save time and wiring. Once calibrated, the marbles were consistently seperated so long as they didn't come through at the same time. We then chose to use a photoresistor to seperate the different colors between the marbles.

Reliability | Time | Efficiency | Innovative | total | |

Pneumatic | 2 | 3 | 4 | 3 | 12 |

Tree Design (magnets) | 1 | 2 | 3 | 4 | 10 |

Spring | 3 | 1 | 1 | 1 | 6 |

Photosensors | 2 | 4 | 2 | 2 | 10 |

Machine Control Capstone Project: Brainstorm

-Brainstorming Ideas:

This was the first order of business, we had to find a way to get our motors to start working. We added a variable counter also as a psuedo-timer to make sure our recycling center didn't go on forever.

We then made a brainstorm where we would work out a way to seperate the marbles (we didn't end up going with this design)

Freddy had the bright idea of adding a spring to our recycling center in order to help seperate the metal and wooden marbles (as opposed to using a magnet)

We also chose to use a photo resistor to differentiate between the different types of marbles.

No comments:

Post a Comment